The Ryburgh Foundry

Part 2. Everitt Adams & Co (Ltd.)

1879-1880

In the Great Ryburgh St. Andrew Churchwardens’ accounts for Jan 13th 1879 there is the first evidence I have seen to date of the foundry trading as Everitt Adams &Co:

Everitt Adams & Co

Repairs to stove as per bill £3-7-6d

On May 31st 1879 in the Norwich Mercury

"At a special Petty Sessions at Fakenham (concerned with school attendance) .....Matthew Peeling, of Great Ryburgh, aged twelve years, an intelligent -looking boy in the employ of Messrs. P.Everitt, Adams, and Co., engineers, was examined as to his attainments, his employers being wishful to retain his services, on the understanding that due attention shall, by them continue to be paid for his mutual improvement. The examination proved satisfactory, and permission was given for his continuance at his situation on the terms stipulated"

The Village School around this time was having problems with attendance and this may be an attempt to find a practical solution to pupils that, just as today, don't fit into the system. Matthew was still employed at the Foundry at the time of the 1881 Census.

From hereon the partnership is increasingly in evidence and 1879 can be seen as the year of the Turnip thinner and the Universal Ploughing Engine in both the technical, national and local press:

Norwich Mercury June 18 1879

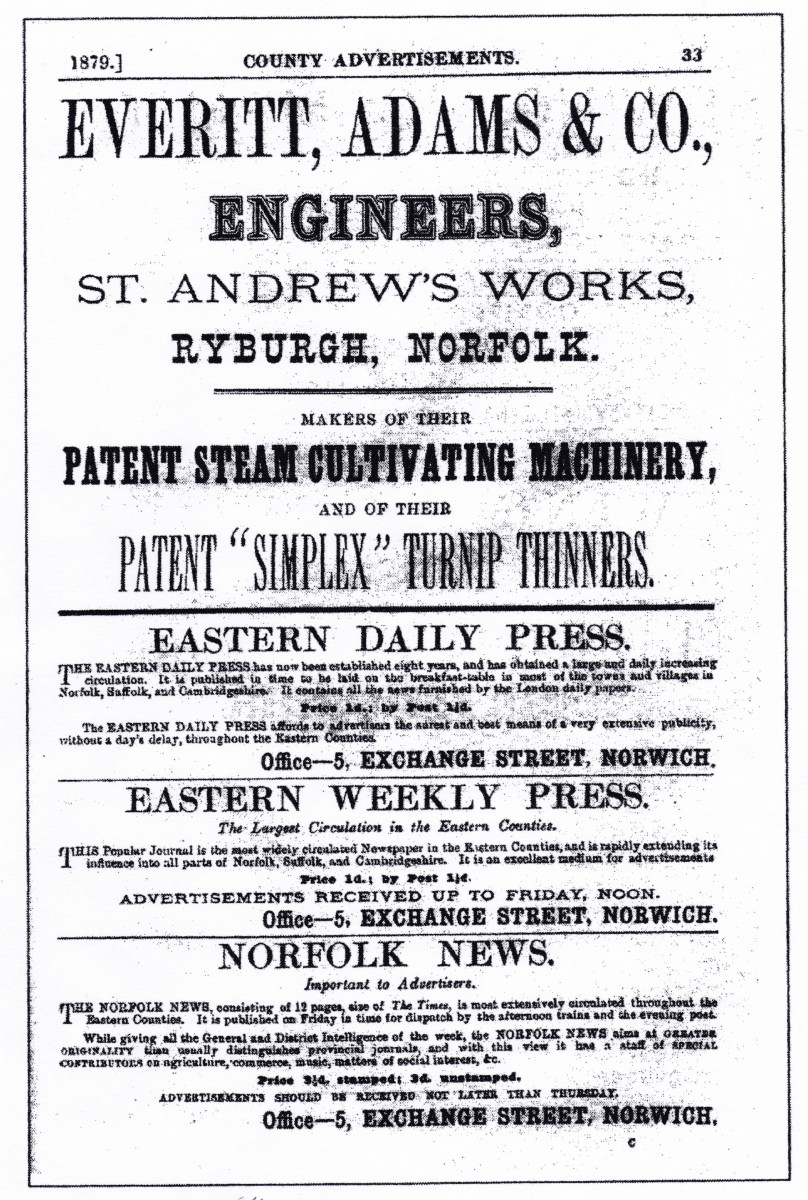

These two products did the rounds of various agricultural shows and the products merited the taking of a large advert in Kelly’s directory for the year.

We now have the foundry premises with the name St. Andrew’s Works which, it is reasonable to assume, was due to Percy’s father and funder Isaac Everitt, who was at the time, Churchwarden at the parish church of St. Andrew Great Ryburgh.

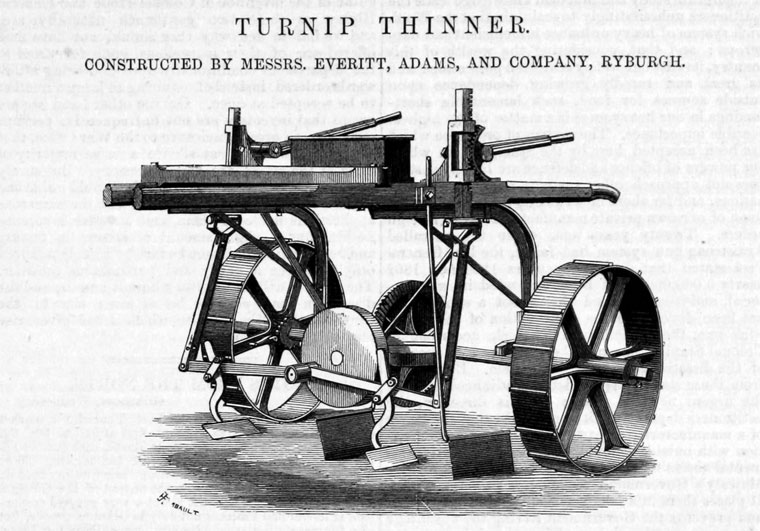

The Turnip Thinner seems now to be produced at Ryburgh as evidenced by the following found in an illustration in The Engineer of July 16 1880

This report from the Bath & West Show reported in The Times June 5 1879:

The greatest novelties in the yard consist of a very effective turnip thinner, newly improved by Messrs. Everitt, Adams, and Co., of Ryburgh, Norfolk.

A report on the efficacy of the demonstration of this machine was deferred to the following day “when the sun will have killed the weeds, and one can better see what the machine has left behind”

W.P.Baker, Phoenix Works King’s Lynn were sole agents for the machine and their advert from June 28 also gives the prices of the two versions:

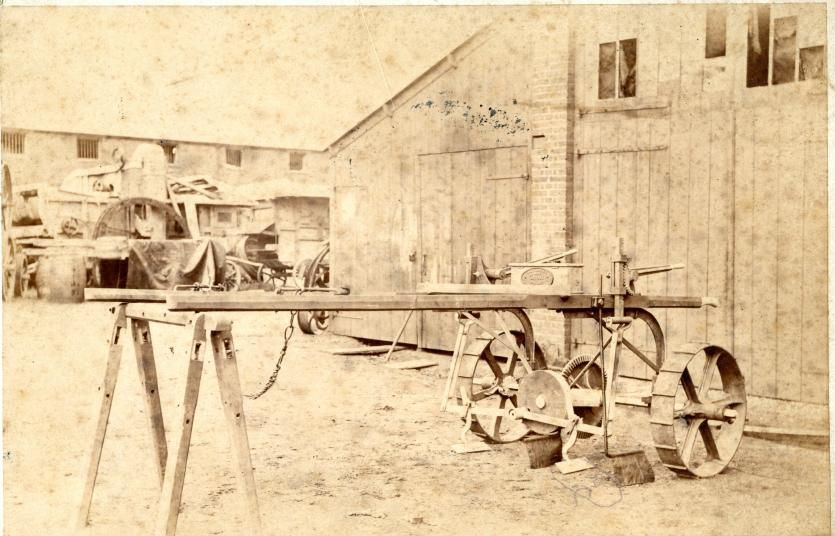

This photograph c1879/80 depicts that very machine standing in the yard at the St Andrew's Works in Ryburgh. The granary building is clearly seen in the background and the wheels of a cultivating engine on the extreme left.(photograph reproduced by the kind permission of the King's Lynn Museum)

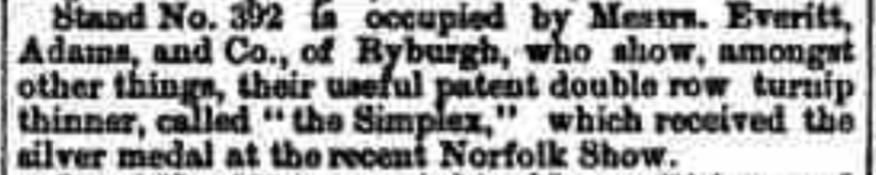

This report from the Royal Agricultural Show July 2 1879 tells of it being a silver medal winner at the Norfolk Show held at Dereham:

Though this was a well received machine in some quarters, it would seem that not everyone had heard of it and which prompted this letter to the editor of the Norfolk News on July 31 1880:

It is interesting to find in 1909 again in the Norfolk News:

So far as exhibits were concerned the Gloucester Royal ranked with the best, but the failure of the weather and attendance will quite outweigh in the opinion of the public its right to take a front place in the records. Farmers are always looking for something new in the way of implements or machinery at these big shows, and the Royal in particular. For many a year we have been anxious too find two machines capable of dealing with the root crop in a way equal , if not superior, to manual work. Many years back, turnip thinners were often seen at our shows, and even on some farms, one of the most efficient of these being brought out by a company at Ryburgh, near Fakenham, but for various reasons, like the double-furrow ploughs, they disappeared, and were no more seen even in a show yard. At the recent Royal, among some fifty entries for the medals offered by the society for new implements or machines for agricultural purposes, were two turnip -thinners, which are said to have shown an advance on previous machinery for this purpose. There is no doubt about it that on real turnip land where daubiness is seldom and clods never, a machine will do almost as good work as the average man is capable of. I have had it done by the Ryburgh machine thirty years ago, and I remember my steward saying that the women singling the crop hardly found any difference in their portion of the work.

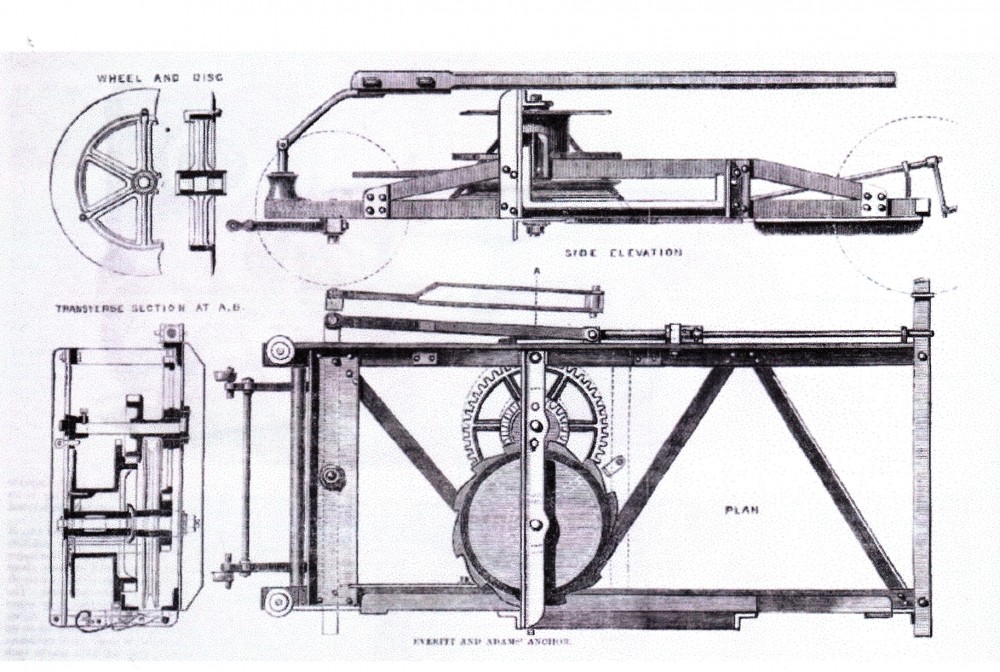

1879 also produced Everitt’ s patent anchors reported in the July 10th issue of the Times

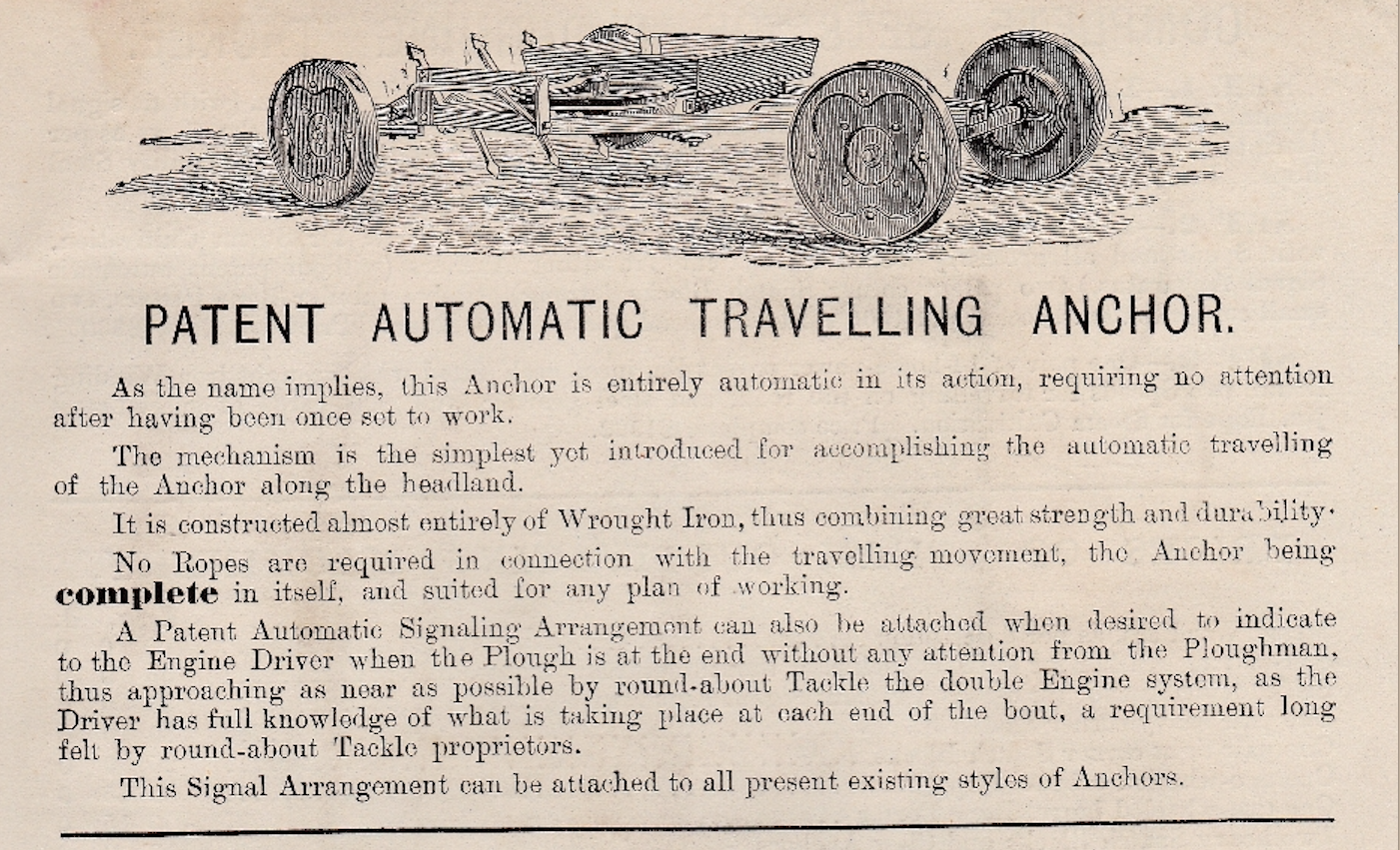

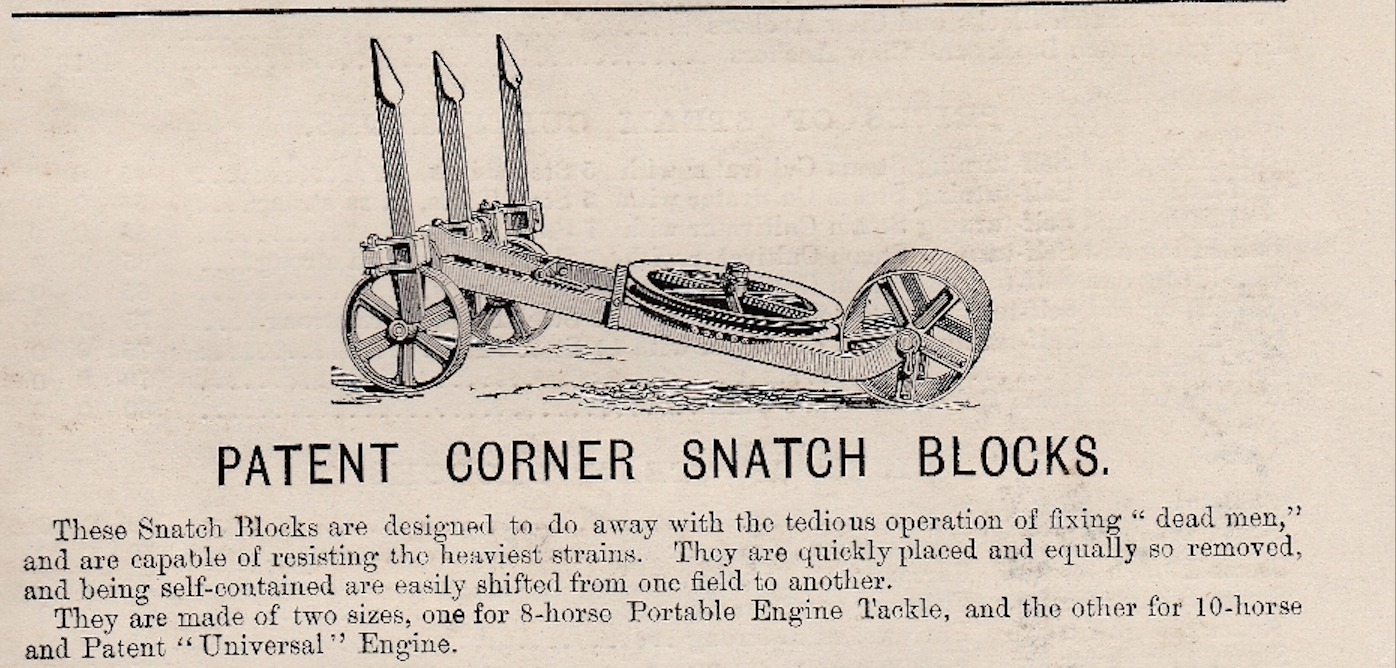

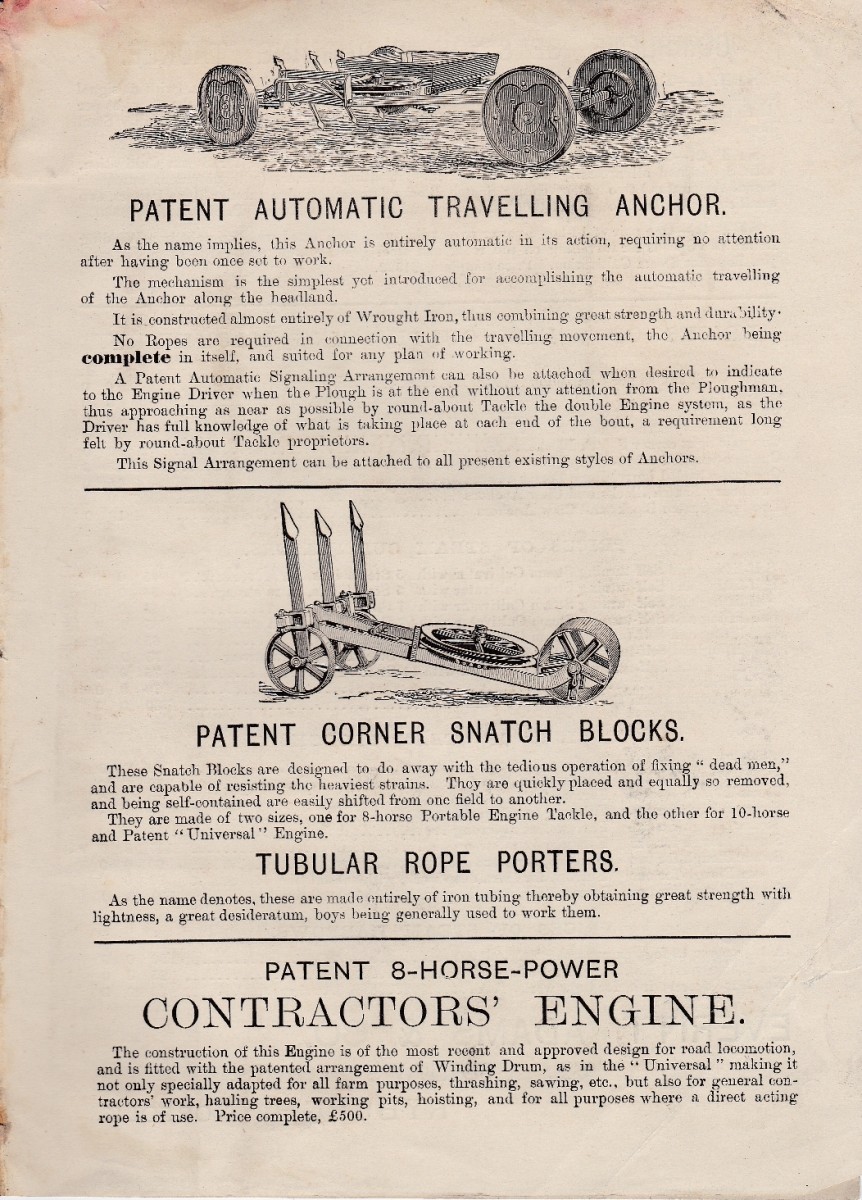

An illustration of this apparatus appeared on the pages of their catalogue:

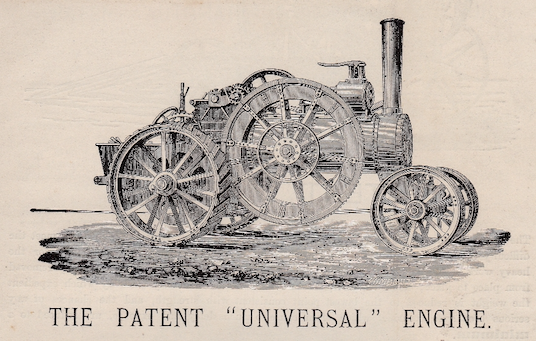

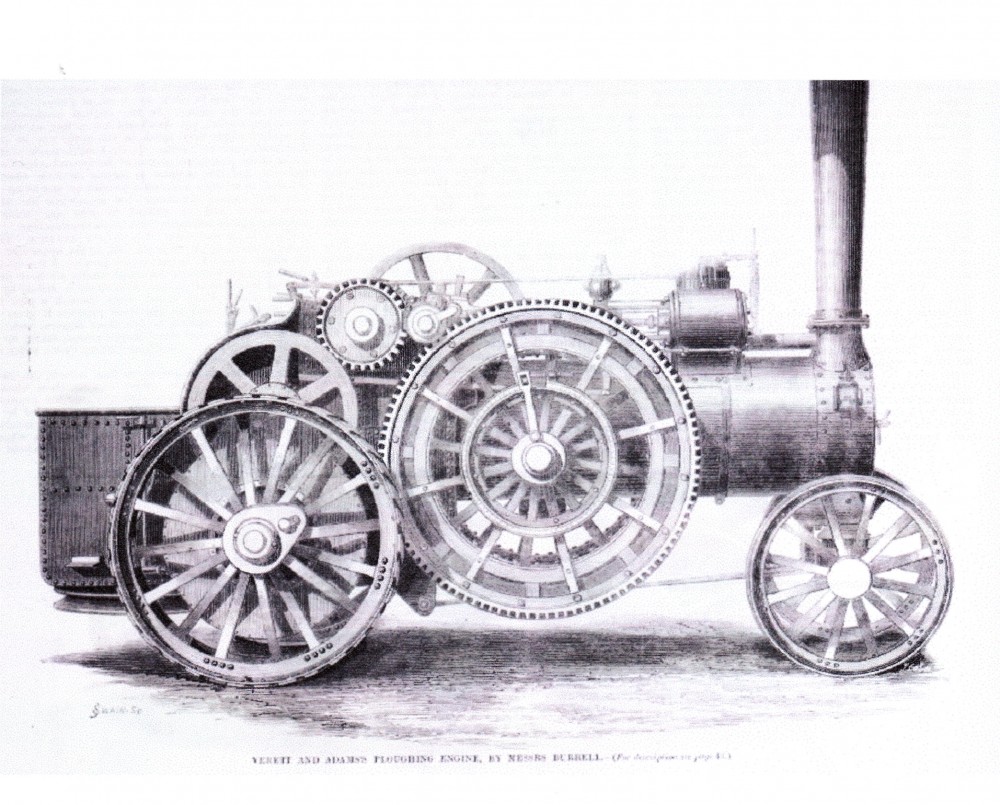

and the engine itself:

The image above was donated to the museum at Gressenhall by Mabel Holman, the daughter of Henry Ely, latterly foundry foreman, who worked at the foundry from its earliest days and certainly was there in the Census of 1881 and so would have known this engine at first hand

The Engineer heralded the engine above in their issue of July 4 1879

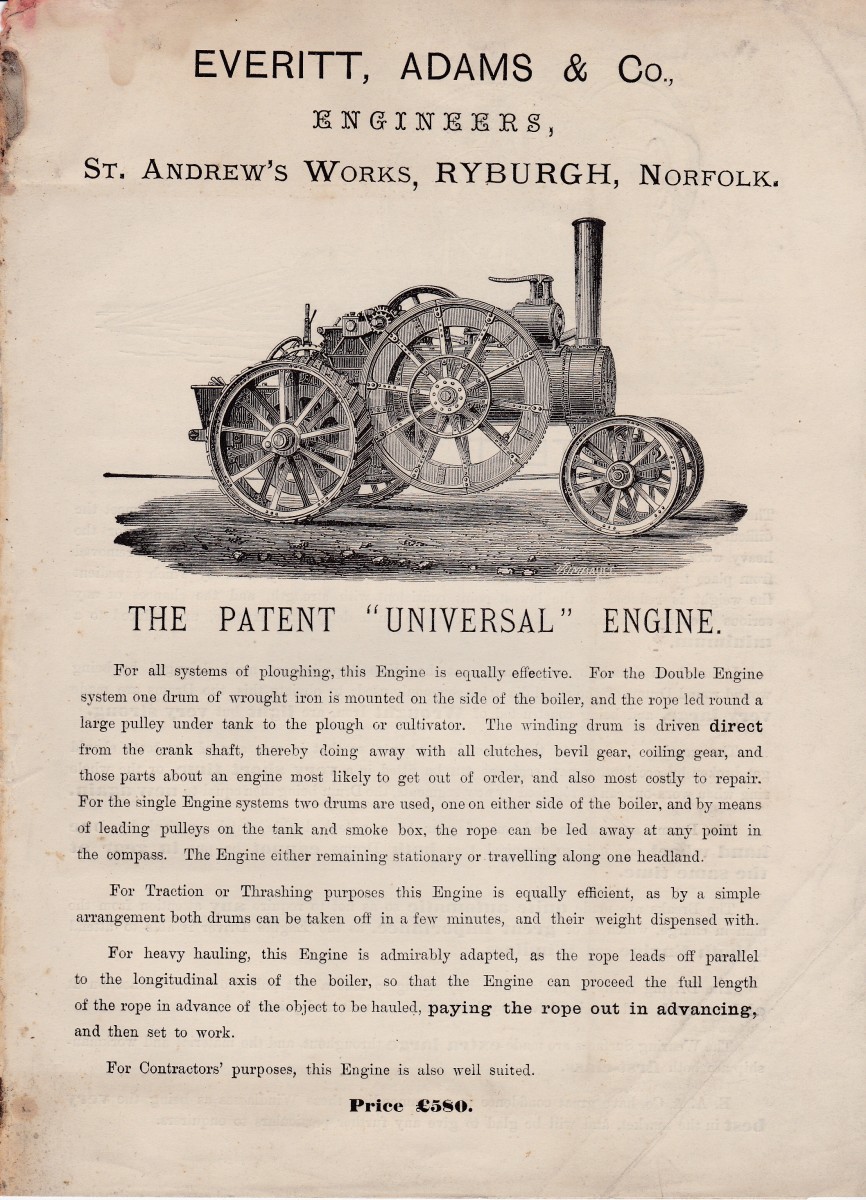

Messrs. Everitt, Adams, and Co., of St. Andrew’s Works, Ryburgh, Norfolk, a new firm, exhibit a very novel ploughing engine, which we shall illustrate in an early impression. One member of the firm has for some years worked ploughing engines; that is to say he has hired them out. In this way he acquired much experience, and arrived by degrees at certain conclusions to what he wanted. The result is the engine to which we refer. It is a very powerful machine, not perhaps quite so well finished as those exhibited by other makers, but obviously capable of doing a great deal of hard work. The spur gearing is of unusually large diameter-an excellent feature. The system of ploughing adopted is quite new. On each side of the engine is mounted a large vertical winding drum, driven by a spur pinion on the crank shaft. Each drum is fitted with a friction brake, to prevent slack. No bevel gear is employed- an important advantage. The drums are easily taken off when the engine is wanted for thrashing or hauling. When employed on the double engine system, one drum only is mounted, and the wire rope is led direct round a large horizontal pulley under the tank direct to the implement. When a single engine is employed, two drums are used, the ropes being led in any desired direction. When we illustrate this engine we shall have more to say concerning it.

The July 16th issue of The Engineer had a more detailed write up and, as promised, an illustration of the Ploughing Engine.

The engine sent by Messrs. Burrell and Sons, of Thetford, we illustrate on page 44.

It is constructed under the patents of Messrs. Everitt and Adams, of Ryburgh.

The first engine of the type ever built was exhibited last year at Kilburn. The prominent peculiarity of the engine is the mounting, on each side of it, of a winding drum, either of which can be caused to revolve by putting a pinion on the crank shaft in gear with the ring of cogs on the drum. These drums are, in fact, vertical windlasses, and wind up the rope which hauls the plough or other implement. If two engines are used, one on each headland, then a single drum on each will suffice; but for roundabout work, both are required; and in order to lead one rope in the proper direction, a horizontal pulley of large diameter is fitted under the foot-plate, and round this the rope is led. Thus the rope from either drum can be led off at any angle. The engine is 10-horse power by the Society's rules-that is to say, it has a cylinder l0in.diameter and 12 in. stroke. The safety valves are loaded to 150 lb. on the square inch. The boiler is of steel, as is all the gearing, but the brackets, road-wheels, and drums are of wrought iron, the latter having cast iron cog rings. The drums are 6ft. 6in. in diameter, and each carries 800 yards of 3/4in. wire rope. A self-acting brake is fitted to each drum. It consists of a hoop, lined with wood, encircling a sheave fixed to the drum. The hoop can be tightened by a screw. On the stud on which the drum revolves is fixed a small ratchet wheel. An arm provided with a click is fixed at its outer end to the brake strap, while at its inner end it embraces the stud. When the drum is winding, the brake carries the arm round with it, the click running over the ratchet wheel; but when the drum is paying out, the click enters the teeth of the ratchet wheel, and the arm then prevents the brake strap from revolving with the drum and in this way the tail rope is kept tight. There are eleven teeth in each of the drum pinions, and 107 teeth in each of the drum rings, so that as the engine makes about 150 revolutions, per minute, when hauling, the drums make nearly 15.5 revolutions in the same time, which corresponds to a speed of implement of, say 310ft. per minute or over 3·5 miles an hour. For ploughing the speed is less than this, the engine being run more slowly, but for cultivating in light land the velocity is higher, the engine making from 200 to 25 0 revolutions per minute. The driving wheels are 18in. wide, and 5ft. 8in. diameter. The leading wheels are 4ft. by 16in. By a very neat arrangement of brackets the pinions driving the drums are kept quite close up to the bearings when in gear. The workmanship of this engine we need hardly add leaves nothing to be desired. The side drums, it may be proper to add, are carried on studs, which are really the arms or ends of astrong axle, bent in the middle to half encircle the boiler, to which it is secured by bolting it between stout angle irons rivetted to the barrel of the boiler……………… A great advance has been made in the matter of automatic anchors; and Everitt’s anchor, which will wind itself either backwards or forwards, and Barfords (Barford & Perkins) are very complete and satisfactory implements

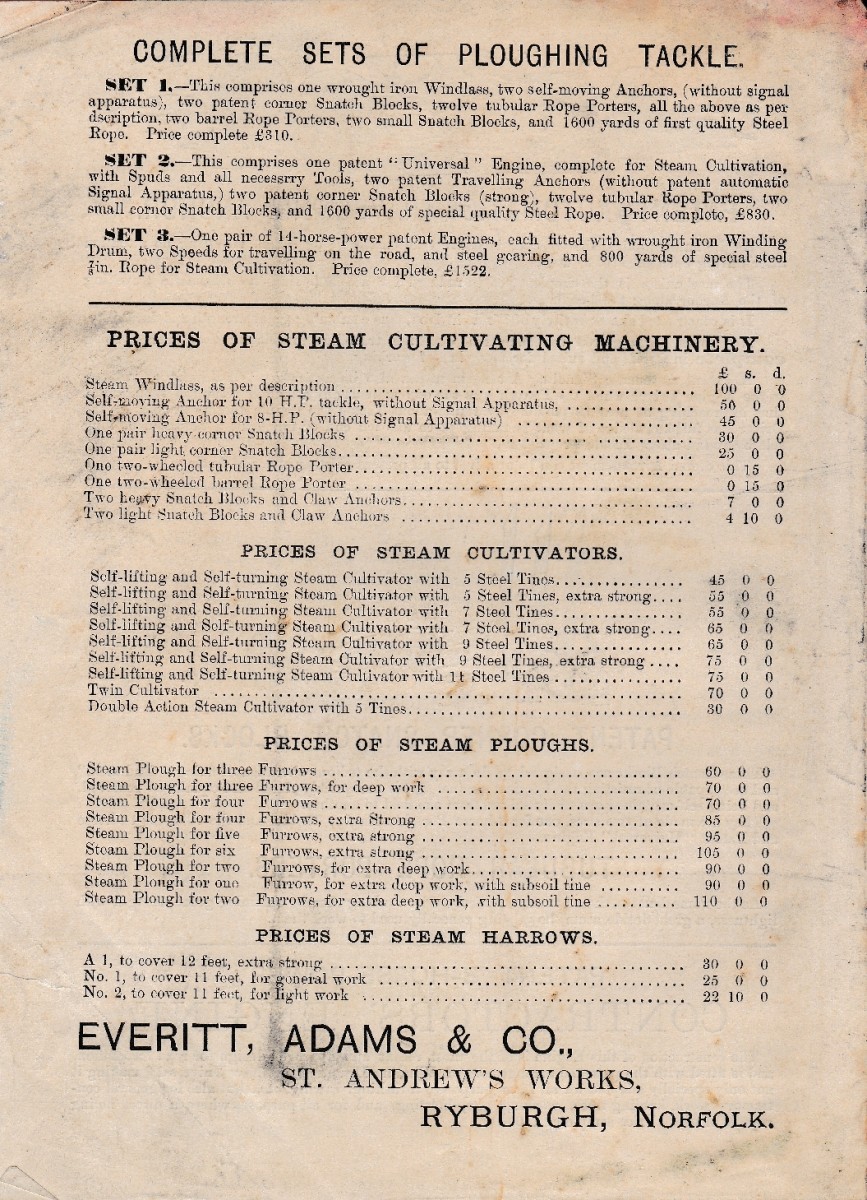

We have in our archive a small illustrated catalogue which must date from c.1879/80 showing what the foundry was intent on producing. These were not cheap machines and the cost of just one of these "Universal Engines" at £580 represented the combined annual incomes of 20 Ag. Labs!

Who was William John Adams?

The partnership with William John Adams (the son of a noted railway engineer) trading as “Everitt, Adams & Co Engineers, ironfounders and agricultural machinists” was fairly short lived. On September 27th 1882 notice is given in the Liverpool Mercury under the heading

"Partnerships Dissolved" Percival Everitt and William John Adams, trading as Everitt, Adams & Co., 35 Queen Victoria Street, London, and at Great Ryburgh, Norfolk, engineers.

William John Adams, pictured below with his wife and family, went to Australia in 1883 where his career flourished. Follow this link for more about William Adams

Everitt & Adams come briefly to life in the press in 1879 as they both seemed to have a desire to “tread the boards”. We already had a review of Percy’s performance at Wells but now the two teamed up, on several occasions to do their party pieces for charitable purposes. In May ‘79 their talents were reviewed at Wimbotsham (in aid of the church choir treat) where Percy brought out “The Frenchman Tra la la bong” again and:

“greater [amusement] still was that afforded by the rendering and impersonation of “The two Policemen” by Messrs Everitt and Adams who met with a tremendous reception and were twice vociferously encored”

In November '79 for the benefit of the Church Restoration Fund at Wells:

“the very effective rendering of Offenbach’s operetta by Messrs Everitt and Adams, was beyond all praise and highly appreciated by the audience.”

Later that same month at Downham, they were clearly getting the bug:

”Mr Percy Everitt’s song,’The Maid and the magpie’ was fairly received…... ‘The Frenchman’ was honoured with applause…... Mr W. Adams’ song was well received..The comic duet ‘The two policemen, or we’ll run them in’ by Messrs Everitt and Adams was vociferously encored twice, and caused roars of laughter, the amateurs being good mimics.”

There were no more such triumphs reported after that and perhaps the honeymoon for the partners was starting to be over as they both start to think there was something more in life to being a successful engineer than a provincial foundry.

The business still had and to make a profit for them and be run efficiently:

Norfolk News March 27 1880

WANTED, for a Small Engineering Works, a Respectable and Inteligent Youth as TIME and STORE KEEPER, and to make himself useful. One with a knowledge of Book-keeping preferred. - Apply , stating age, experience, and salary required, to EVERITT,ADAMS, & Co.,[St.] Andrew's Works Ryburgh, Norfolk.

We see in a joint Patent Notice further product development:

February 1880:

Percival Everitt and William J. Adams, Ryburgh, Norfolk improvements in machinery for cutting chaff. Dated February 10 1880.

Norfolk News June 19 1880:

Messrs. Everitt, Adams, & Co. (Ryburgh) showed several new productions, the first being a new patent, portable chaff-cutting, cleaning, and bagging machine, the gearing of which is entirely of steel, the feeding apparatus very efficient, and the construction substantial yet not cumbrous. The three operations of cutting, cleaning and elevatimg are done by the knife wheel, the number of the moving parts being thus reduced to the lowest point. A patent safety plate is affixed, by which it is impossible for a man to get his arm past the rollers to the knives, and this is a great improvement.

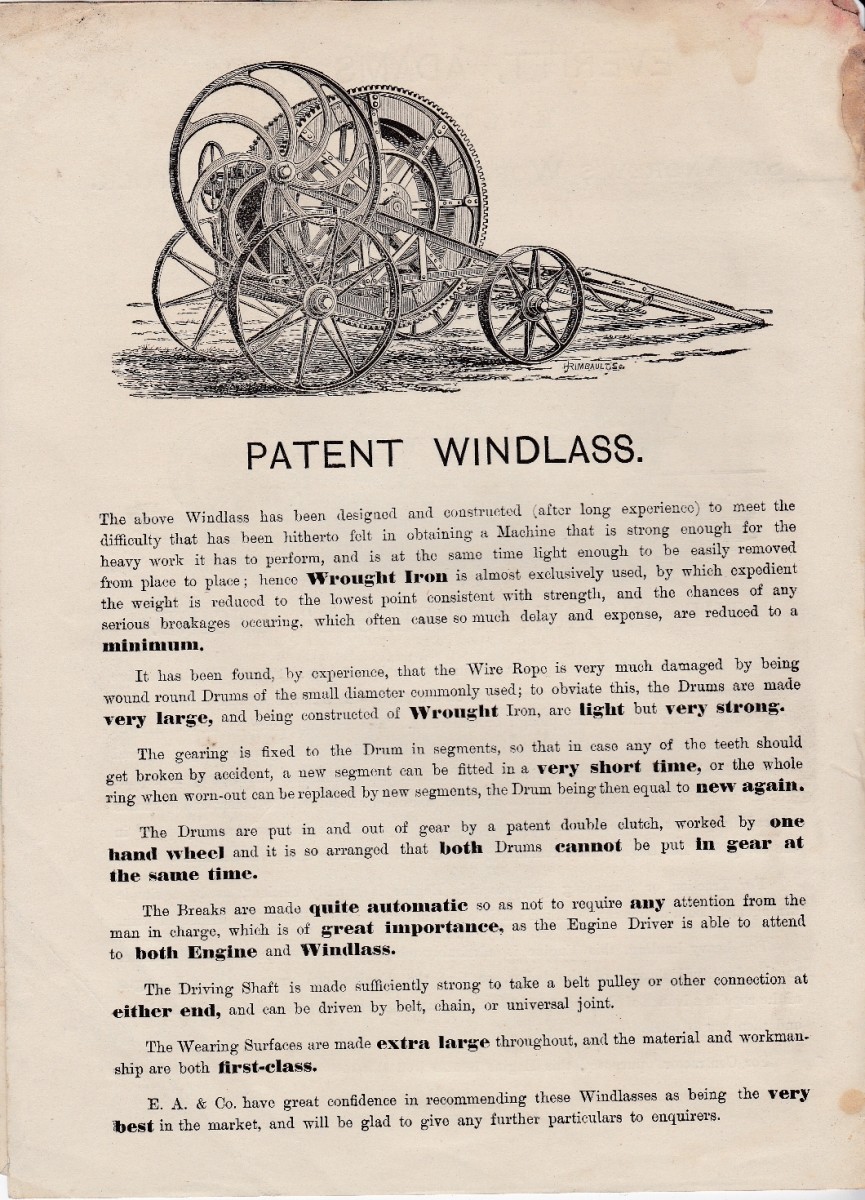

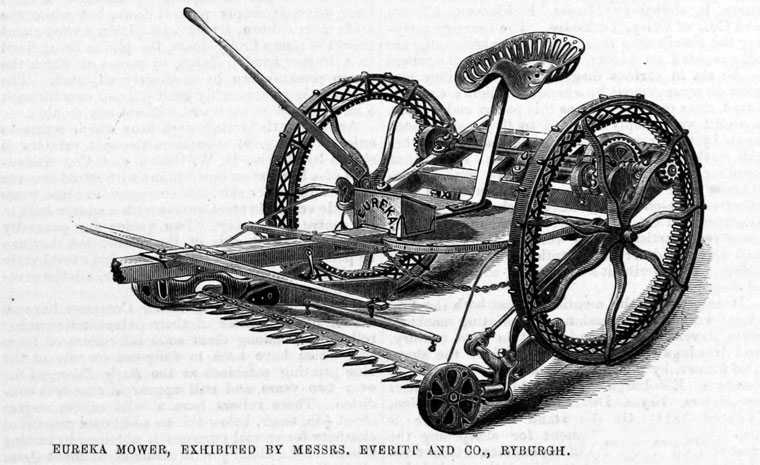

Other features are the new Eureka central draught grass mower, cutting a six-feet swath, and easily drawn by two horses; and the automatic travelling anchor, for eight-horse-power round-about steam ploughing tackle.(see catalogue above)

Graces Guide ( to whom thanks are due for the use of this and some of The Engineer illustrations.) has the following illustration posted with the date of 1880

The Eureka Mower was an American machine as seen in the advertisment below found in the 1890 "American Agriculturist" .

The connection with Everit Adams & Co is probably that they were importing agents and keen to promote the machine. This from the Thetford & Watton Times July 3 1880

Later on the 17 July in the Sporting Gazette there is found a little more information:

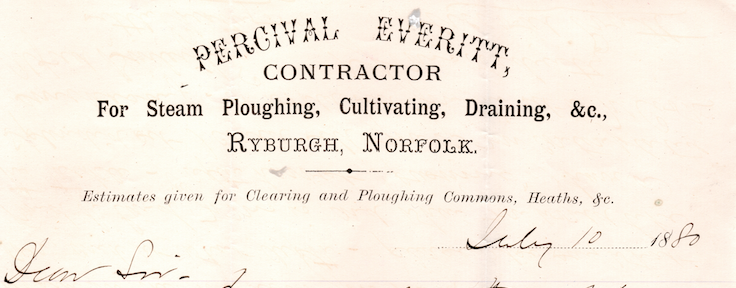

Meanwhile, Steam Cultivation was still a going concern for Percy Everitt:

His partner in this enterprise at some stage became William A Wilson though it is not apparent from this letter heading of 1880 (The full story of this correspondance will soon be available HERE)

There were still ongoing brushes with the law which must have been very much part of being a steam proprietor!

May 1880

STEAM LOCOMOTIVES.- Percy Everett of Great Ryburgh engine proprietor, was charged by Supt. Mumford with unlawfully allowing a steam locomotive engine to be travelling on the highway at Mundford on the 2nd ult., without having a person on foot in front. Mr Everett did not appear, but Mr. A.Wilson appeared on his behalf and pleaded guilty, stating that the men had been continually cautioned, but the lad who ought to have been in front had travelled many miles that day and as tired, and finding a long straight piece he got upon the engine to ride.- Fined £1 and costs £1 5s. 11d.

*************

Part 3 Everitt, Adams & Co. Limited 1881-1884